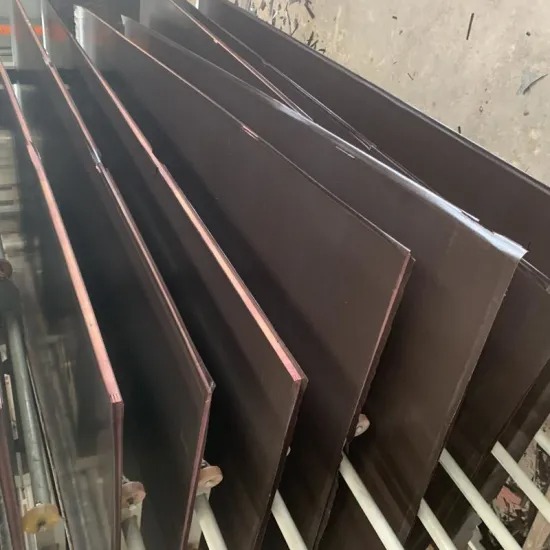

Brown Film Faced Plywood

Brown Film faced plywood is lightweight, resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut. Treating the film faced plywood’s edges with waterproof paint makes it highly water-and wear-resistant. Due to its durability and easily handled surface it can be used in open environment in construction and building e.g. warehouses, railway wagons, floors and sidewalls of trucks etc.

Description

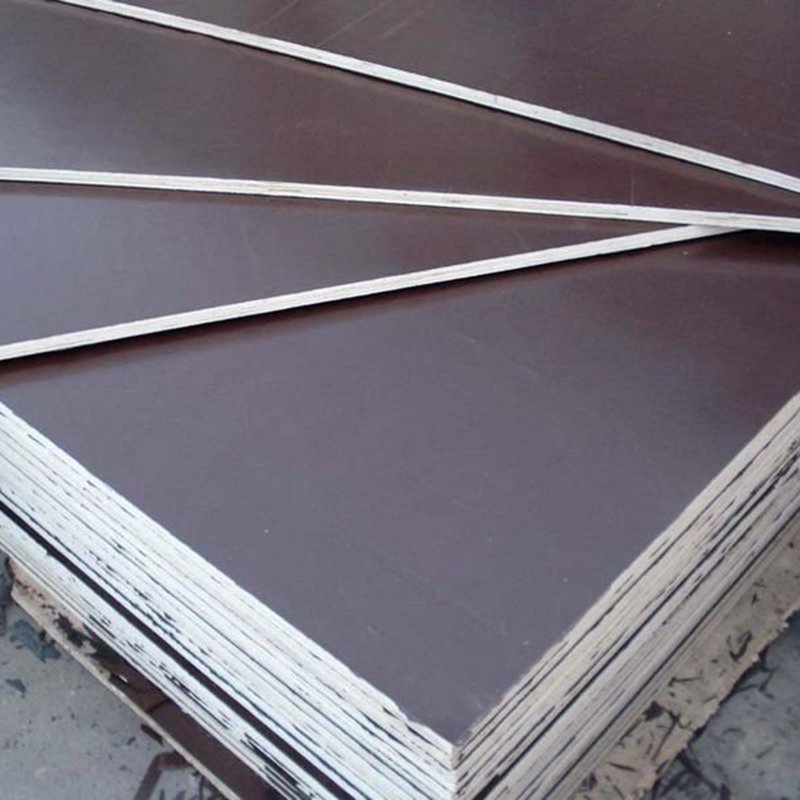

Film Face Plywood – water proof plywood

F/F – smooth/smooth

F/W – smooth/wiremesh

Definition;

Grade: F/F, F/W, W/W

Thickness Tolerance: ± 0.5mm

Glue Type: Phenolic WBP, Melamine WBP, MR

Density: 680 – 700 kg/m³(birch) 580-300kg/m³(poplar)

Film Color: DBO – Dark Brown Opaque. Different colors and film weights are available on request.

Film Weight : 120 g/m² – 400 rotations according to Taber test (EN 438-2) 220 g/m² – 750 rotations according to Taber test (EN 438-2)

Glue type: Phenol-formaldehyde (WBP), Melamine (Urea-melamine-formaldehyde)

Pressing Process: One time hot pressed, two times hot pressed

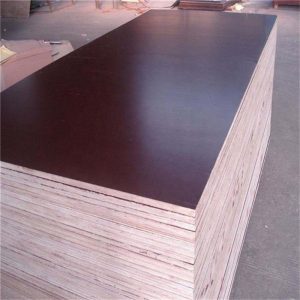

Wide range of size and thickness. Customized size are available.

Standard sizes:

| Thickness Available(mm) | Thickness Available(imperial) | Sizes in mm | Sizes in feet |

| 3mm | 1/8“ | 1220 mm x 2440 mm | 8 ft ×4 ft |

| 6mm | 1/4“ | 1220 mm x 2440 mm | 8 ft ×4 ft |

| 9mm | 3/8“ | 1220 mm x 2440 mm | 8 ft ×4 ft |

| 12mm | 1/2“ | 1220 mm x 2440 mm | 8 ft ×4 ft |

| 15mm | 5/8“ | 1220 mm x 2440 mm | 8 ft ×4 ft |

| 18mm | 3/4“ | 1220 mm x 2440 mm | 8 ft ×4 ft |

| 25mm | 1“ | 1220 mm x 2440 mm | 8 ft ×4 ft |

| 32mm | 1 1/4“ | 1220 mm x 2440 mm | 8 ft ×4 ft |

Advantages:

Extremely durable and weather resistant overlay

High quality surface of the concrete

Dimensionally stable

Easy to clean and cut

Weather and boil proof bonding

Widely used in exterior building construction.