Plywood dimensional tolerances

This part of the scope GB/T 9846 specifies the dimensional tolerances for the length, width and thickness of flat plain plywood, as well as the tolerance requirements for the straightness and verticality of the edges. This part applies to entire sheets of plywood, not plywood assembled by miter joints, finger joints or other ends.

The provisions of the following documents are incorporated into this part by reference to this part of GB/T 9846.

Determination of thickness, width and length of wood-based panels — Determination of verticality and edge straightness of wood-based panels

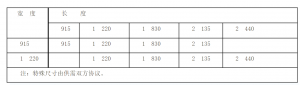

Dimensions the dimensions of plywood shall be specified in Table 1. Table 1 Plywood dimension in mm

4 Tolerance Requirements

4.1 Tolerance of Length and Width Width length

What are the characteristics of steel grid?

Material saving: a way of saving material under the same load conditions, and correspondingly, reducing the material supporting the structure. Reduce investment: save material, save labor, save time, free cleaning and maintenance. Easy construction: fixed with bolt clamp on the pre-installed support…

s

4.1.1 According to GB/T19367.1 — 2003 5.2 length and width of measuring board 4.1.2 Plywood length and width deviation is soil 2.5mm.

4.2 Thickness Tolerance

4.2.1 Measure the thickness of the plate according to 5.1 in GB/T 19367.1 — 2003.

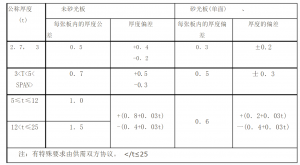

4.2.2 Plywood thickness tolerance shall be in accordance with table 2. Table 2 Thickness tolerance unit is mm

Nominal thickness (t) is not sand plate sand plate (single), each board inside the thickness tolerance of thickness deviation within each plate thickness deviation of thickness deviation of 2.7, 3 0.5 + 0.4 + / – 0.2-0.2-0.3 3 < T < 5 < SPAN > 0.7 0.5 0.3 0.5 and 0.3 + 1.0 + 5 T 12 or less or less (0.8 + 0.03 T) – (0.6 + 0.4 + 0.03 T), (0.2 + 0.03 T) a (0 4+ 0.03t) 12<t≤25 1.5 Note: Special requirements shall be agreed by both parties. < / t 25 or less

4.3 Edge straightness tolerance

4.3.1 Measure the edge straightness of the plate according to GB/T 19367.2 — 2003 5.2.

Plywood edge straightness tolerance to 1 mm/m.

4.4 Verticality tolerance

4.4.1 Measure the perpendicularity of the plate according to 5.1 in GB/T 19367.2 — 2003.

Plywood verticality tolerance to 1 mm/m.

5 warp degrees

5.1 Plywood with nominal thickness of more than 6 mm shall not exceed 0.5% for superior grade, 1% for first-class grade, and 2% for qualified grade.

5.2 Warpage measurement shall be carried out according to Appendix A. GB/T 9846.2-2004 Attached A (Normative Appendix) measurement method of warpage

A. 1 Place the concave surface of the plywood upward and without any external force on the horizontal table, place the metal ruler or tautly rope on the board along the two diagonal directions respectively, and measure the maximum chord height and diagonal length between the board surface and the ruler or rope with A measuring instrument, accurate to 1 mm.

A. 2 The warpage is calculated by equation (A.1), accurate to 0.1%.

A. 3 Calculate the warpage of the two diagonal directions respectively, and the larger one is the warpage of the board.